——A One-Stop Solution from Design to Delivery, Powered by Globally Certified Factories

summary:

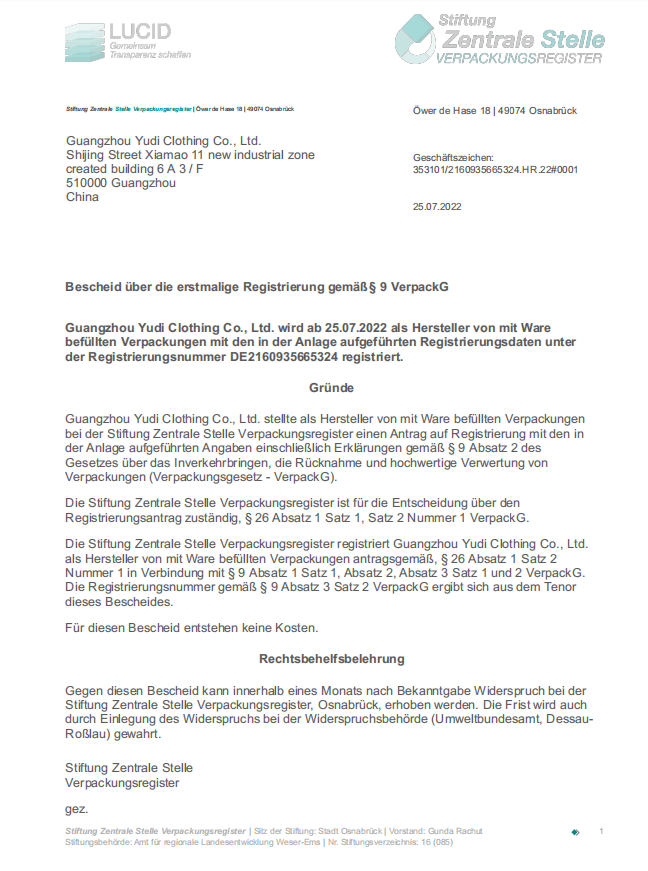

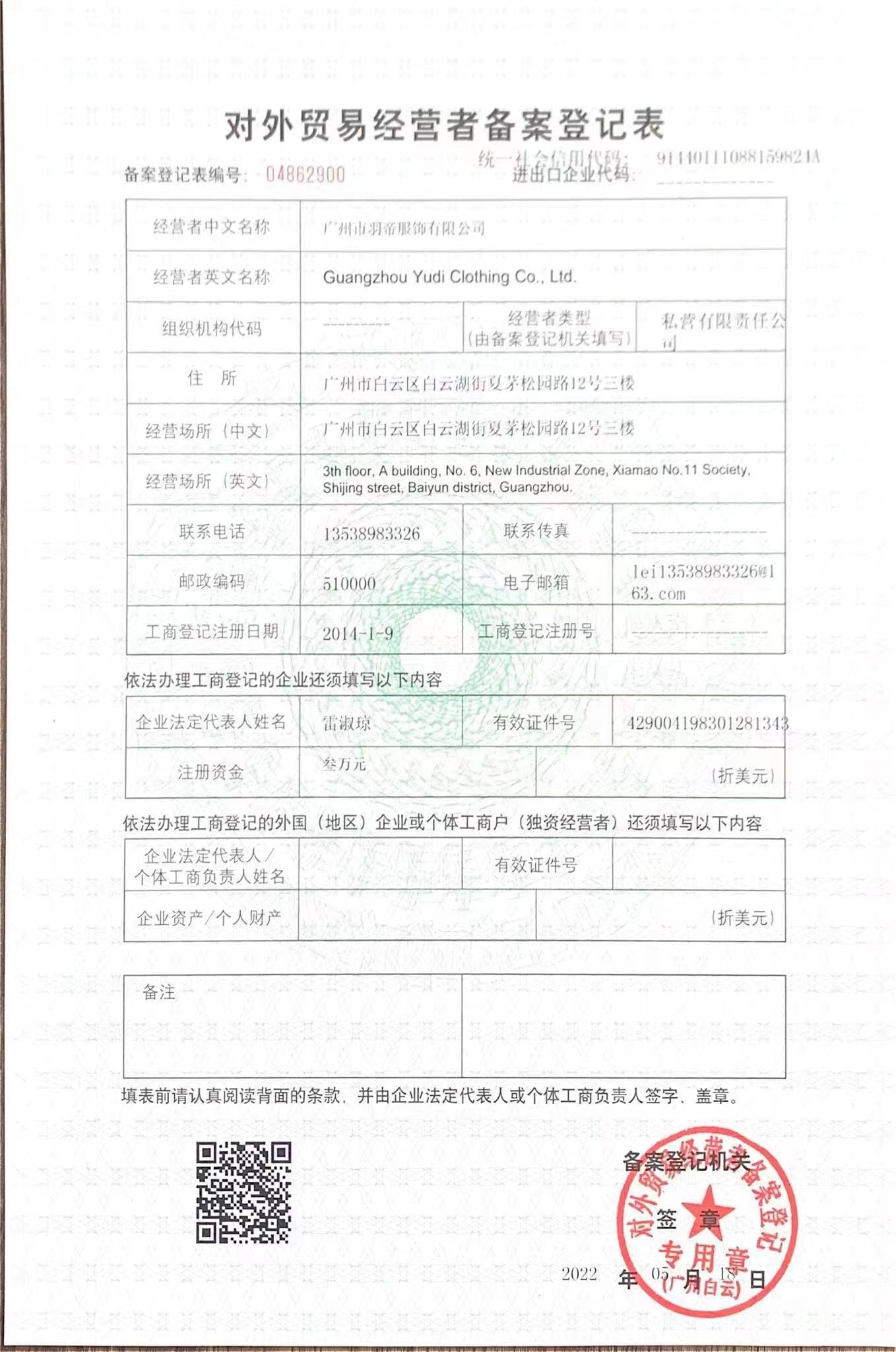

YUDI-CLOTHING, with 21 years in the apparel industry and 11 years in global trade, offers full-chain services from design to delivery through its own factories. Backed by ISO 9001, ISO 14001, Oeko-Tex Standard 100, and other certifications, we empower brands worldwide to thrive with quality, efficiency, and sustainability.

I. YUDI-CLOTHING: 21 Years of Industry Legacy, 11 Years of Global Trade Excellence

As a veteran in China’s apparel sector, YUDI-CLOTHING’s journey mirrors the transformation of “Made in China” to “Created in China.” Since [year of establishment], we have:

- Served 30+ Countries: Clients include fast-fashion brands in Europe/US, e-commerce sellers in Southeast Asia, wholesalers in the Middle East, and emerging designers in China.

- Annual Capacity Exceeds 5 Million Pieces: Covering knitwear, woven, denim, and sportswear, with MOQ as low as 50 pieces for rapid replenishment and large-scale customization.

- Tech-Driven Innovation: AI design, 3D virtual sampling, and intelligent cutting systems boost efficiency by 40%, reducing lead times to 15–30 days.

II. Why Choose YUDI-CLOTHING? – Global Certifications, Quality Assured

1. International Certification Framework

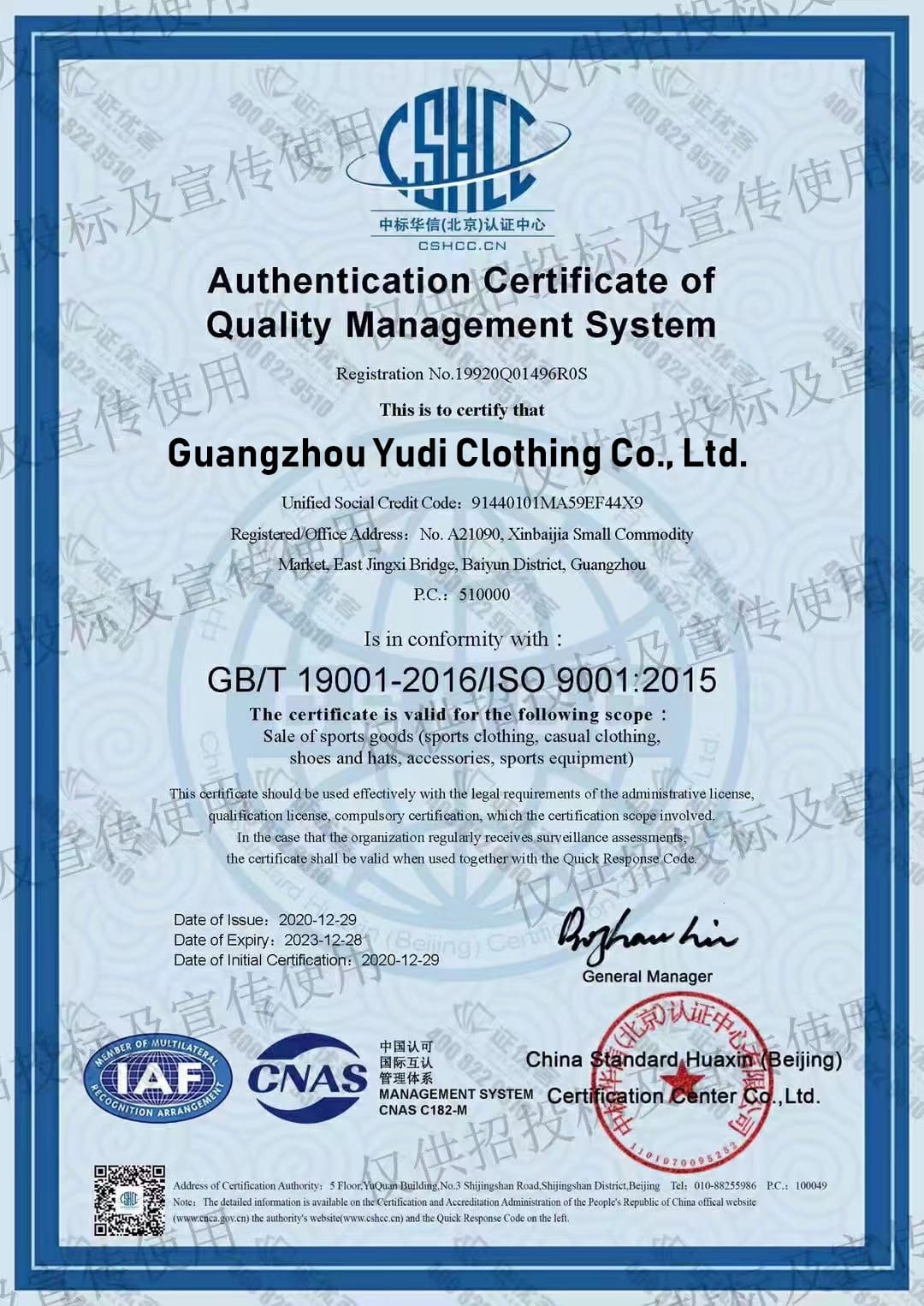

- ISO 9001: Quality Management: Zero-defect production with a defect rate below 0.3%.

- ISO 14001: Green Manufacturing: 85% wastewater recycling and 25% lower carbon emissions than industry average.

- Oeko-Tex Standard 100: Safety & Eco-Friendliness: All fabrics pass harmful substance tests, with Class A certification for infant wear.

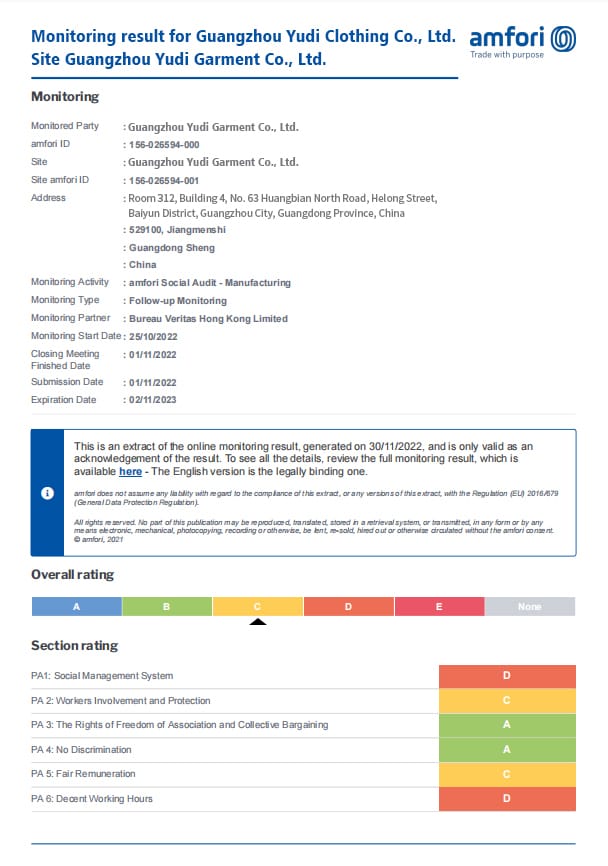

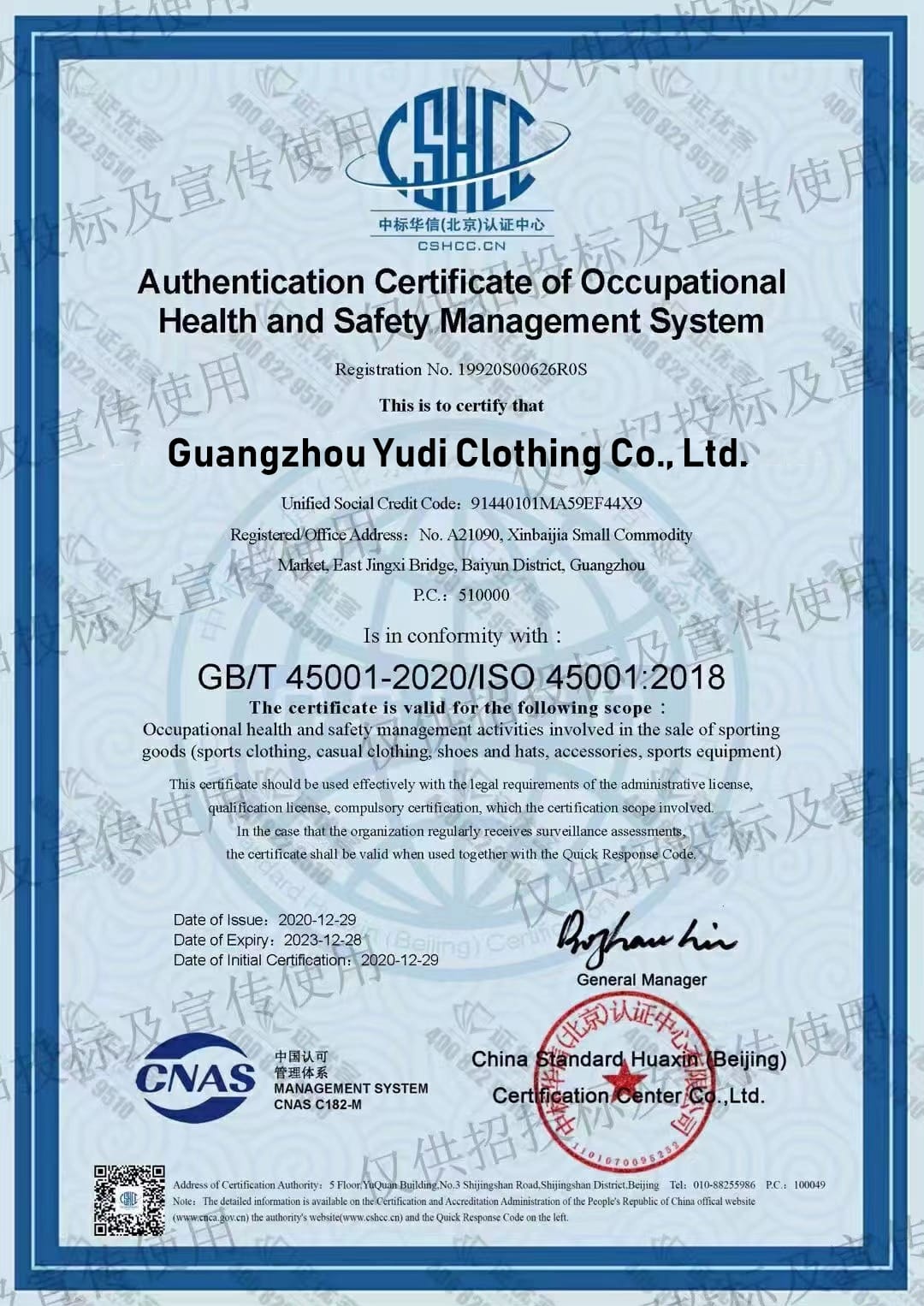

- SA8000 & WRAP: Social Responsibility: Compliance with international labor standards and employee rights protection.

- 3C Certification: Specialty Categories: Mandatory product certification for functional apparel (e.g., outdoor jackets).

2. Full-Chain Advantages

- Design & R&D: 15-member senior designer team offering end-to-end services from sketches to 3D prototypes.

- Fabric Supply Chain: Strategic partnerships with 50+ suppliers in Guangzhou’s Zhongda Textile Market, stocking over 2,000 fabrics for rapid sampling.

- Production & Delivery: Flexible capacity via owned factories and a network of partner workshops to handle seasonal demand fluctuations.

III. Core Services: From OEM to ODM, Tailored to Diverse Needs

1. OEM (Original Equipment Manufacturing)

- Precision Craftsmanship: German Gerber cutters and Japanese Juki sewing machines ensure ±0.5cm accuracy.

- Tiered Quality Control: AQL 2.5/4.0 standards with optional third-party inspections.

2. ODM (Original Design Manufacturing)

- Trend Insights: Monthly Global Apparel Trends Whitepaper covering color, silhouette, and fabric trends.

- Bestseller Incubation: Created a “UV-Blocking Ice Silk Jacket” for a Southeast Asian client, selling 500,000 units in 3 months.

3. Sustainability Solutions

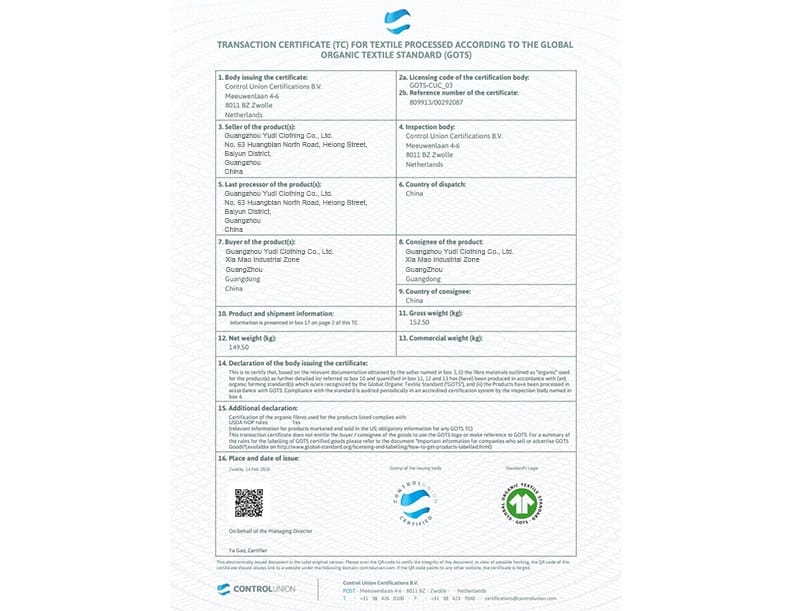

- Eco-Friendly Fabrics: GRS-certified recycled polyester, organic cotton, and Tencel options.

- Carbon Footprint Tracking: LCA (Life Cycle Assessment) reports for every order to support ESG disclosures.

IV. Case Studies: From OEM to Brand Co-Creation Transformations

Case 1: North American Niche Brand “EcoStyle”

- Challenge: High return rates (12%) due to subpar OEM quality.

- Solution: YUDI-CLOTHING reengineered production processes with Oeko-Tex fabrics, reducing returns to 2%.

- Outcome: 300% annual sales growth and recognition as a “Sustainable Fashion Pioneer.”

Case 2: Chinese Emerging Designer “LUMI”

- Need: Urgent delivery of 200 couture wedding gowns within 2 weeks.

- Response: Activated “Express Lane” with 48-hour design approval and 72-hour production, achieving 100% on-time delivery.

V. How to Partner with YUDI-CLOTHING? – A 3-Step Process for Efficient Collaboration

1. Requirement Gathering

- Provide design sketches/references, quantities, timelines, and budgets.

- Receive a complimentary Cost Estimation Sheet and Production Schedule.

2. Sampling & Approval

- Prototypes delivered in 3–5 business days, with unlimited revisions until satisfaction.

- Sign formal contracts after sample approval, with a 30% deposit.

3. Mass Production & Delivery

- Real-time production tracking with full transparency.

- Final payment triggers release of quality reports and logistics tracking.

VI. Future Vision: Driving Industry Innovation with Technology

Embracing AI, metaverse, and carbon neutrality, YUDI-CLOTHING is accelerating:

- Virtual Fitting Rooms: AR try-on tech with Alibaba’s DAMO Academy to reduce e-commerce returns.

- Blockchain Traceability: End-to-end transparency from fabric sourcing to logistics.

- Zero-Carbon Factory: 100% renewable energy by 2025, setting a new industry benchmark.

Conclusion:

At YUDI-CLOTHING, we believe “Quality is the foundation of brands, efficiency is the edge in competition, and sustainability is the passport to the future.” Whether you’re a startup, e-commerce seller, or traditional trader, let our 21 years of expertise propel you to global success.

Act Now:

- Visit our website: [Insert Website URL] to download the Global Apparel Trade Guide.

- Scan the QR code: [QR Code Image] for the latest industry insights.