Textile printing stands as fashion’s unsung hero—a transformative artistry that breathes life into fabrics, weaving vibrant patterns and meticulous details into wearable masterpieces that resonate with seasonal trends and timeless style. Far more than mere decoration, this craft is the backbone of innovative design, enabling manufacturers to translate creative vision into tactile reality. From daring geometric motifs to delicate floral embellishments, each printing technique boasts its own unique strengths, tailored to elevate distinct aesthetics.

Mastery of these methods is the key to crafting collections that captivate. Screen printing delivers boldness and depth, ideal for statement-making graphics. Digital printing thrives on precision, reproducing intricate artworks with photorealistic clarity. Rotary printing ensures consistency for large-scale production, while discharge printing lends a vintage softness to designs. Together, they form a toolkit of possibilities, empowering designers to blend artistry with industry demands.

Ready to unravel the alchemy behind runway-ready textiles? Let’s embark on a journey through the fascinating world of textile printing—where technology meets tradition, and every thread tells a story. Discover how these techniques not only follow fashion’s pulse but often set it, turning simple cloth into canvases of self-expression.

Introduction

Printing is fashion’s secret weapon—it turns fabrics into show-stopping designs that align with trends and seasons! From bold patterns to intricate details, textile printing brings creativity to life. For manufacturers and designers aiming for high-quality, eye-catching pieces, mastering the right techniques is key. Ready to dive into the world of textile printing? Let’s explore!

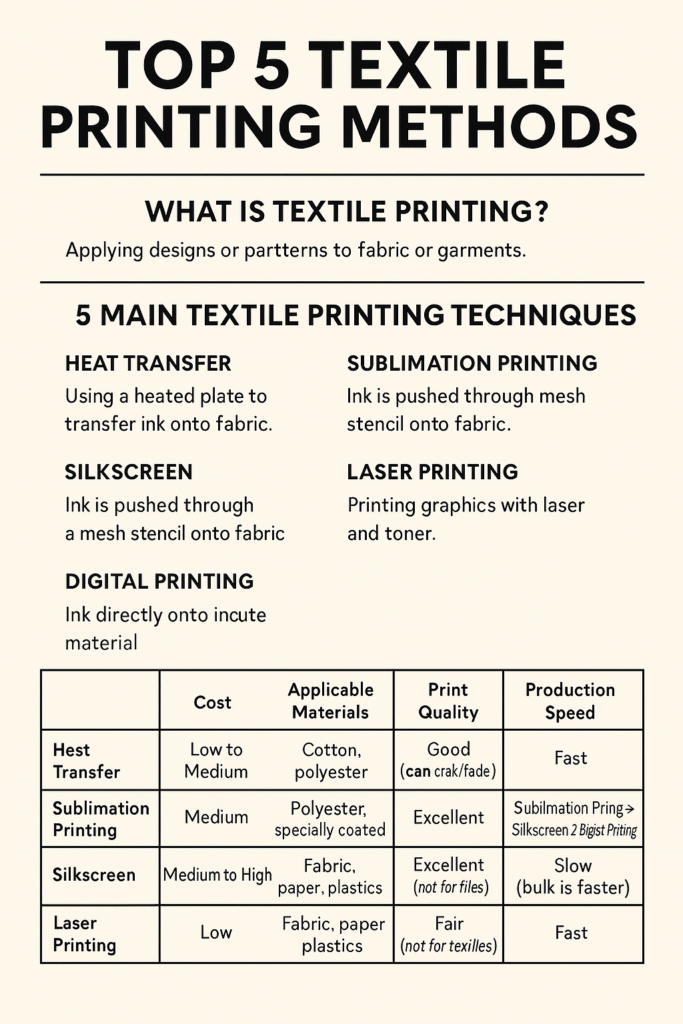

What Is Textile Printing?

Think of textile printing as painting with precision. Unlike dyeing, which colors fabric evenly, textile printing places color exactly where the design requires. The result? Unique, multi-colored patterns applied to garments or fabrics, turning blanks into wearable art.

Top 5 Textile Printing Techniques

Each printing method has distinct benefits depending on fabric type, production volume, and design complexity. Here’s a breakdown:

1. Heat Transfer Printing

A popular and user-friendly method, heat transfer involves printing an image onto a special transfer paper and using a heat press to transfer the design onto the fabric.

Cost: Low to Medium

Best for: Cotton, Polyester

Pros: Vibrant, detailed designs; fast turnaround

Cons: May crack or fade over time

2. Sublimation Printing

This technique uses heat to turn dye into gas, embedding it into polyester fabric.

Cost: Medium

Best for: Polyester, coated fabrics

Pros: Permanent, vibrant prints that won’t crack or fade

Cons: Limited to light-colored synthetic materials

3. Silkscreen (Screen Printing)

A traditional and widely used method where ink is pushed through a mesh screen stencil.

Cost: Medium to High

Best for: Fabric, paper, plastics

Pros: Rich, opaque colors; durable

Cons: Time-consuming setup; less ideal for small runs

4. Laser Printing

Laser printers use toner and heat to transfer designs, mostly for paper and some synthetics.

Cost: Low

Best for: Paper, some synthetic blends

Pros: Fast and sharp text/image output

Cons: Not ideal for fabrics; may damage materials

5. Digital Printing

Uses inkjet technology to print designs directly onto fabric.

Cost: Medium

Best for: Cotton, polyester, silk, blends

Pros: Great for complex designs, quick turnaround, suitable for small batches

Cons: Less vibrant on dark fabrics; may fade faster

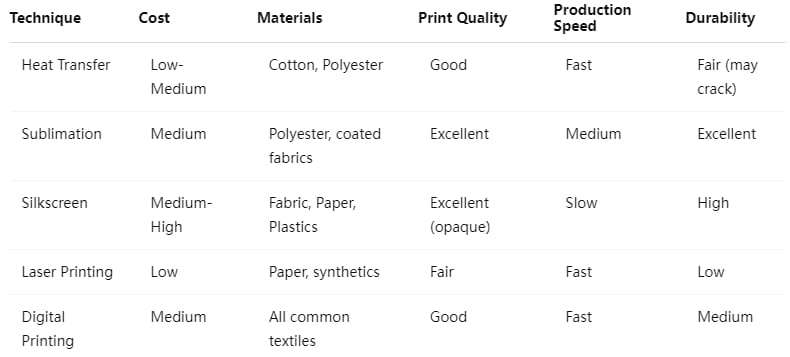

Comparison Chart: Textile Printing Techniques

How to Choose the Right Printing Method

Fabric Type: Cotton works best with heat transfer or digital printing; polyester favors sublimation.

Design Complexity: Detailed multi-color prints? Choose digital. Simple bold logos? Silkscreen is cost-effective.

Quantity: Large batches? Go with silkscreen. One-off or small orders? Digital is your friend.

Durability: Sublimation is the winner here—it fuses with the fabric and resists wear.

Budget: On a budget? Try heat transfer or laser (if paper-based). High-end? Sublimation or silkscreen.

Turnaround Time: Digital and laser methods are the quickest. Silkscreen requires prep but excels in bulk jobs.

Need help choosing? Contact YUDI Clothing — our expert team will guide you to the perfect solution!

Conclusion

From timeless techniques like silkscreen to high-tech solutions like digital and sublimation printing, the right method can elevate your product line. Whether you’re launching a fashion collection or customizing workwear, understanding textile printing helps you make informed choices.

Want tailored advice or custom printing? Connect with YUDI Clothing today and bring your vision to life!