In the clothing workshop, have you ever noticed how fabrics can have different shades referring to the Pantone color number, even from the same batch? It’s a real puzzle for designers and buyers! They often wonder why fabrics from the same manufacturer can look so different. Is it a quality issue or just a natural part of the dyeing process? While it might seem straightforward, it actually involves a lot of factors in textile printing and dyeing. Once you dive into the dyeing process, you’ll see that these color differences are pretty common and don’t necessarily mean the fabric is low quality!

Once you really understand the fabric dyeing process, you’ll see that color differences are totally normal! It’s just part of how fabrics are made and doesn’t mean there’s anything wrong with the quality. So, those slight shade variations? They’re just a natural part of the journey of creating beautiful textiles!

The Wonderful Process of Dyeing Cloth

Dyeing is the process of combining textile fibers with dyes. It determines the final fabric color. This process appears to be a simple color giving, but it is actually a complex chemical reaction process.

- The raw material cloth needs to go through a strict pre-treatment process, including desizing, boiling, bleaching and other steps. The chefs do this to remove natural impurities and paste residue from the processing process. This step directly affects the effect of subsequent dyeing.

- In the dyeing stage, the dyeing factory penetrates the dye into the fiber through high-temperature and high-pressure processing. This process requires precise control of temperature, PH value, dye concentration and other parameters. Modern printing and dyeing plants generally use high temperature overflow dyeing machines, although this equipment has a high degree of automation, it is still difficult to completely eliminate small differences between batches.

- Next comes the finishing process. This part is also crucial. After dyeing the fabric needs to be fixed color, soft treatment and other processes to ensure the color fastness and wear performance. Each process can have an impact on the final color.

Various Causes of Color Difference

In the context of large-scale industrial production, every variable in the dyeing process can lead to color differences in the process of fabric making.

1. Quality of the Dye Itself

First of all, the dye itself is an important factor affecting color. Even if it is the same brand, or the same batch of dye, its active ingredient content may have small fluctuations. This fluctuation is amplified in mass production, resulting in different colors of dyed fabric.

2. Differences in Temperature and Concentration of Dye Solution

The temperature of the dye solution and the concentration of the dye may vary slightly from batch to batch. Even if the workers operate in strict accordance with the standard, the temperature fluctuations, the solubility of the dye and other factors will still affect the dyeing effect. The temperature of the dyeing solution is slightly higher or lower, which may cause the adsorption effect of the dye to change, resulting in different shades.

3.The Change of PH Value of Dyeing Bath

The change of PH value of dyeing bath will also affect the dyeing effect. Different types of dyes have different PH requirements. Even a slight PH shift can cause color differences. In addition, the amount of additives added in the dyeing bath, water quality and other factors will also affect the final color.

4. Time and Humidity

The time the dye spends on the fabric making plays a big role in the final color. If it’s too short or too long, the color can be uneven. Humidity also affects how the dye spreads and sticks to the fabric, making it harder to get a consistent color. While experienced workers can manage this, it’s still difficult to control perfectly. In large-scale production, even small environmental changes can lead to noticeable color differences.

5. Equipment Differences

Did you know that the equipment used in dyeing can change the color of fabrics? Different machines have varying precision levels, and as they age, they can create uneven dyeing. Even within the same factory, using different machines or containers can lead to color variations, all based on the Pantone color number! It’s fascinating how much technology impacts our textiles!

6. Fabric Structure and Absorption

Did you know that even similar fabrics can behave differently when dyed? Their structure and water absorption vary, which affects how much dye they soak up. Tighter weaves absorb dye differently than looser ones, leading to those unexpected color variations. It’s amazing how these little differences can create such unique results in the final product!

Ways to Reduce the Color Difference of Cloth

For the Manufacturers

Faced with the inevitable color difference problem, modern printing and dyeing enterprises have established a strict quality control system.

- First of all, standard laboratory testing is carried out before production to determine the best process parameters. This includes testing the properties of raw fibers, dyes, and the production of standard samples.

- In the production process, advanced color measuring instruments are used for real-time monitoring. These instruments can accurately measure fabric color data and compare it with standard samples. When deviations are detected, the system automatically adjusts the process parameters.

- Final inspection is also indispensable. Each batch of fabric needs to undergo strict visual inspection and instrument testing. Only products that meet the color difference standards can leave the factory. This multi-level quality control system effectively ensures the consistency of product quality.

For Consumers

- Require samples: Before the bulk purchase, you can ask the manufacturer to provide samples to ensure that the color is consistent.

- Batch control: When purchasing, you can ask the manufacturer whether there is strict batch control, and require the production batch to be marked.

- Tolerance range: For fabric color differences, you can maintain a certain tolerance. After all, color difference is a natural phenomenon that is difficult to completely avoid in the dyeing process.

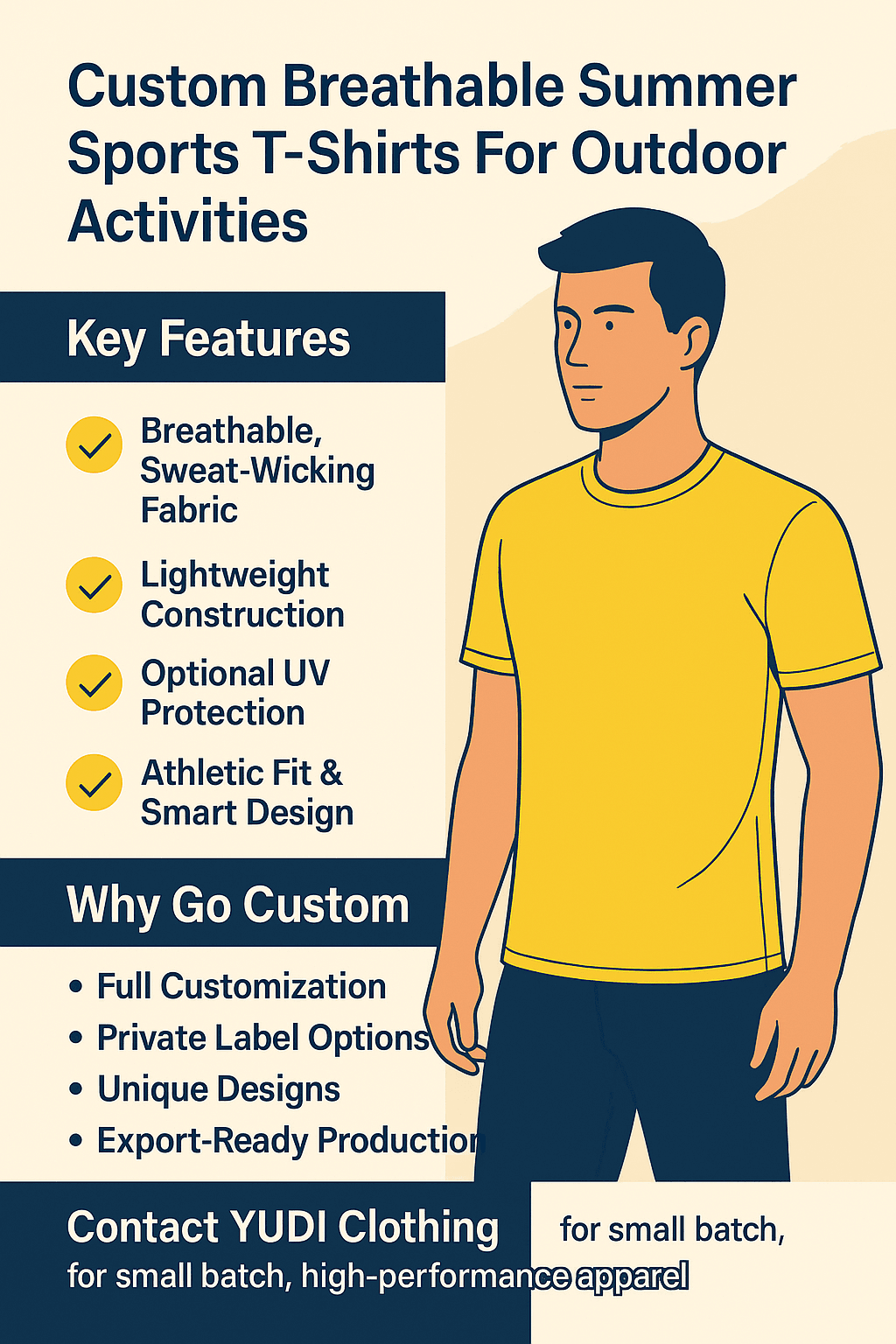

- Choose the right partner: You can choose some manufacturers with excellent production quality to minimize the difference to ensure the quality of the fabric. YUDI Clothing is a good choice. With the progress of technology, the color difference problem of the cloth produced by YUDI Clothing has gradually been effectively controlled. However, if we want to completely eliminate it, we still need continuous technical optimization and strict production management. If you want to learn more about fabric, click on the website to consult now.